MIM Parts

MIM Parts

MIM parts are complex metal parts produced by metal injection molding technology. Metal Injection Molding is a new metal components manufacturing method. Meanwhile, comparing to conventional metalworking method like forging or casting, Metal Injection Molding has better performance in small size, complex geometries metal parts production with high volume quantities. As noticed, MIM form metal parts shape with injection molding process, which is similar to plastic injection molding and high-pressure die casting. However, MIM parts are able to perform high mechanical properties equal to wrought materials, and excellent dimensional tolerance control.

MIM Parts in Process

Metal injection molding (MIM) is a metalworking technology. In MIM process, we mix very fine metal powder with binder material to create feedstock, then this feedstock will be formed and solidified by injection molding process. These parts combine of metal powder and binder with geometry structure are named as– Green part.

After molding, chemical or thermal debining operations will be applied to remove binder materials. MIM parts after debindingare called– Brown part.

At last, sintering process will densify metal powders by high temperature in furnaces. Then we will get —Sintered part.

Sintered parts can be treated like forging or casting metal parts, it can be welded, soldered, blued, hardened, tempered, polished, filed, and ground. Any operation you can perform on forging or casting parts, will perform same on sintered parts post-manufacturing.

MIM Parts Properties

Although MIM metal powder is expensive than normal stock, and its specific molds are horrendously expensive. We never ignore MIM parts advantages, it is high effective for small size parts with complex geometries and high volume. Which is quite expensive to produce by alternative or classic metalworking methods.

Complex Geometries

Normally, MIM parts can get any complex structure you need in product development or high quantity production.

High Tolerance

MIM parts have high dimension accuracy for any special requirement. Our minimum tolerance will be ±0.5% on dimension and ±0.3% on target.

Excellent Surface

The MIM parts surface normally will achieve 1μm, so it can satisfy normal industry requirement without further secondary operations. For special MIM parts surface treatment, our multiple secondary operations will guarantee excellent chemical and physical properties for you.

High Production Quantity

With multi-cavity tooling usage, MIM parts offer high production rates of 10,000 pieces per day.

Various MIM Material

MIM parts have widely material range like: stainless steel, low alloy steel, iron-based, titanium, etc.

Now, MIM parts have wide application in various fields of industry: Electronics, Medical, Industrial, Automotive.

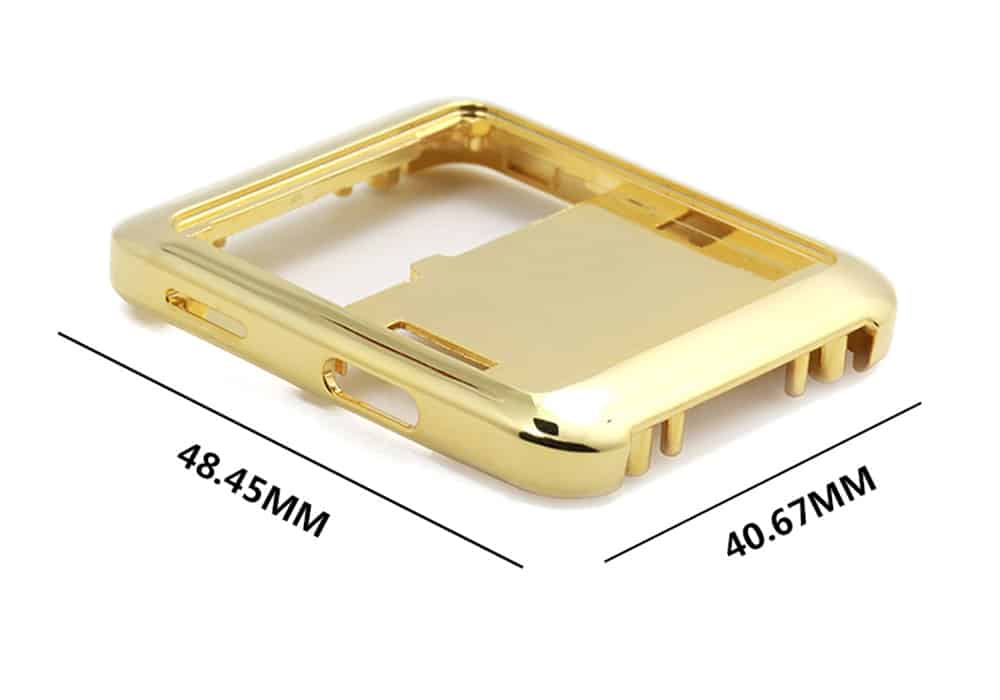

Electronic MIM Parts

MIM Parts are suitable for consumer electronic equipment in electronics industry. Its complex structure and perfect appearance are most suitable for connecting plugin in household appliances’ assembly process. High tolerance is perfect for laptops and mobile phones with precision fitting requirement. Minimum wall thickness of 0.10 mm with high light treatment.

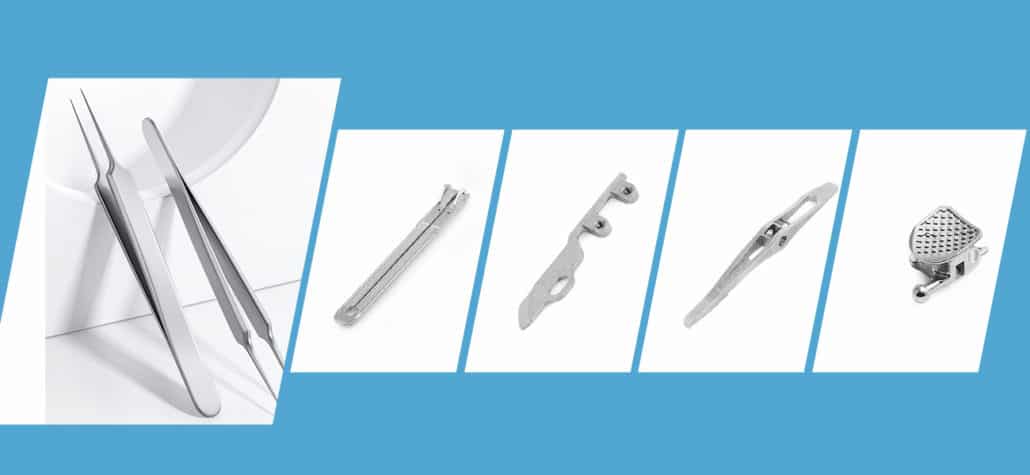

Medical MIM Parts

Our MIM parts in medical devices including: orthodontic brackets, surgical instruments, forceps, scissors, sewing units, drug delivery devices, surgical implants, hearing aids, dental equipment & implants, B-ultrasonic instrument parts.

MIM parts are becoming more cost-effective than traditional investment casting, such as orthodontic device manufacturing process. We can produce this device by stainless steel with high strength, smooth and precision.

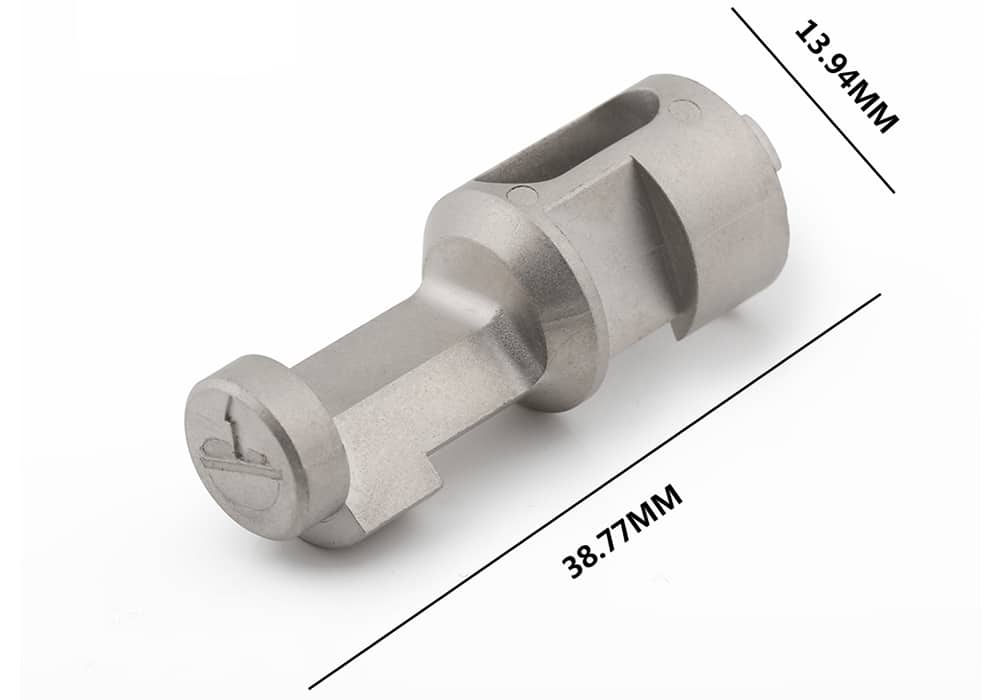

Industrial MIM Parts

ZCMIM provide a wide range of customized MIM parts for different industrial application with various materials, such as: micro gears, drones, smart wearable devices, pepper spray, machinery components.

Automotive MIM Parts

Automotive industry requires high procurement rate for small complex parts or tools. It has high requirement of small size and lightweight MIM parts in electrical system, fuel system, interiors, power transfer system, and safety system. Our MIM Parts are widely as automotive component for vanes, valves, connecting rods, valve guides, parking brake.